Ogata Village, Akita Prefecture, has been selected as the first of the Decarbonization Leading Areas initiated by the Ministry of Environment starting in FY2022, and has now begun to take concrete steps toward this goal. This article discusses the importance of district heating, which is a challenge for Ogata Village, and issues related to Japan's environmental energy policy, especially thermal policy, as seen through specific initiatives.

* This article was originally published in Graduate School of Economics, Kyoto University, on “No. 339 The 4th Generation District Heating and Japan’s Thermal Policy: Japan’s Challenges Seen through the Efforts of the Ogata Village Decarbonization Leading Area”(No.339 第4世代地域熱供給と日本の温熱政策〜大潟村脱炭素先行地域の取り組みから見える日本の課題). Translation by ISEP.

By IIDA Tetsunari

Founder & Chairperson, Institute for Sustainable Energy Policies

Initiatives in Ogata Village

Ogata Village was adopted as one of the first “Decarbonization Leading Areas” in April 2022 1 Ogata Village, “Selection as the First Decarbonization Leading Area,” April 28, 2022. (in Japanese) . The village’s proposal, which aims to create a village with 100% renewable energy, was made together with cooperating businesses including Institute for Sustainable Energy Policies (ISEP). The Decarbonization Leading Areas are in line with the national regional decarbonization roadmap established in September 2021, which calls for the creation of 100 Decarbonization Leading Areas and their spread throughout the country to achieve carbon neutrality in Japan by 2050 2 Council for National and Local Decarbonization, Cabinet Secretariat (in Japanese).

The decarbonization initiative is focused on the use of renewable energy for power generation in the consumer and business sectors. Ogata Village is developing solar PV systems and storage batteries to address this issue, as well as a district heating system using rice husks, which are generated in large quantities in the area. This is an attempt to simultaneously achieve local economic value creation, energy independence, and decarbonization through the use of rice husks, a waste product (a local issue), as a renewable energy resource for thermal use.

Ogata Village, with a population of over 3,000, was created in the 1950s through reclamation of the Hachiro Lagoon. As a result, residential, commercial, and business buildings are concentrated in one location, making it easy to introduce district heating as an urban form. Since the start of exchanges with Denmark in 2014, a feasibility study and basic design for the introduction of district heating have been completed in cooperation with the Danish technical team and ISEP 3 Ogata Village has been working to materialize district heating through the Ministry of Internal Affairs and Communications’ “Distributed Energy Infrastructure Project Master Plan Development” in 2015 and the Ministry of Environment’s “Decarbonized Community Development Model Formation Project” in 2019. .

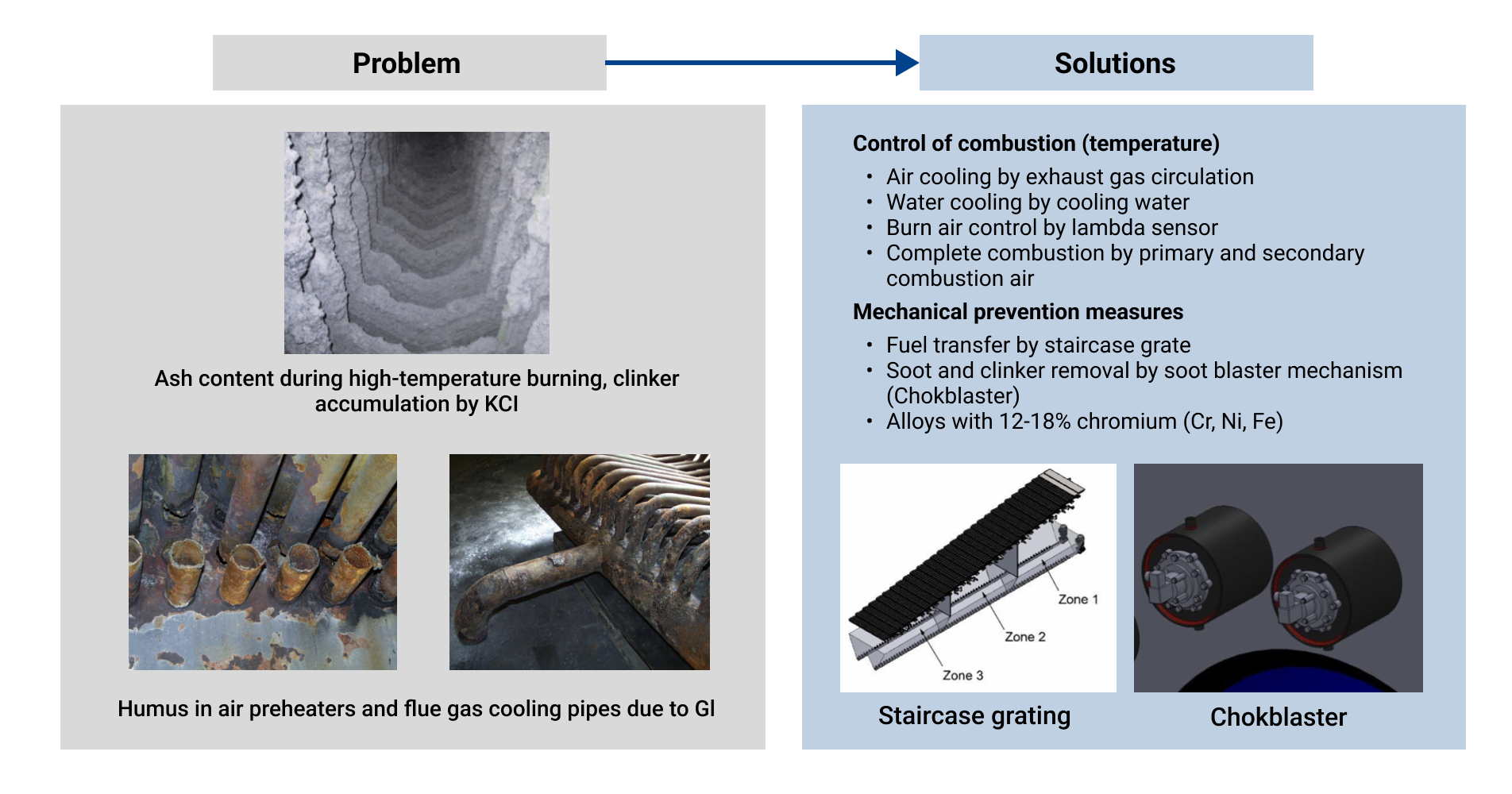

Rice husks, with their high calorie content, are a good fuel and appear to be easy to burn, but they present a serious challenge. When burned at high temperatures, the combustion ash contains crystalline silica, which has been identified as a carcinogen 4 Crystalline silica (cristobalite) is almost non-existent in nature except for minerals, but amorphous silica crystallizes when rice husks and rice straw are heated to high temperatures. The International Agency for Research on Cancer (IARC) states that people suffering from silicosis are at risk of developing lung cancer and recommends that crystalline silica dust be controlled to < 0.1 mg/m3 for occupational health reasons. In Japan, the Occupational Safety and Health Law and its enforcement ordinance stipulate “labeling requirements”. . After conducting joint research with a Danish boiler company and Akita Prefectural University, both of which have extensive experience in combustion of agricultural residue in boilers, we were able to reach a combustion method and boiler structure that does not produce crystalline silica, which led to our selection as a Decarbonization Leading Area.

The 4th Generation District Heating

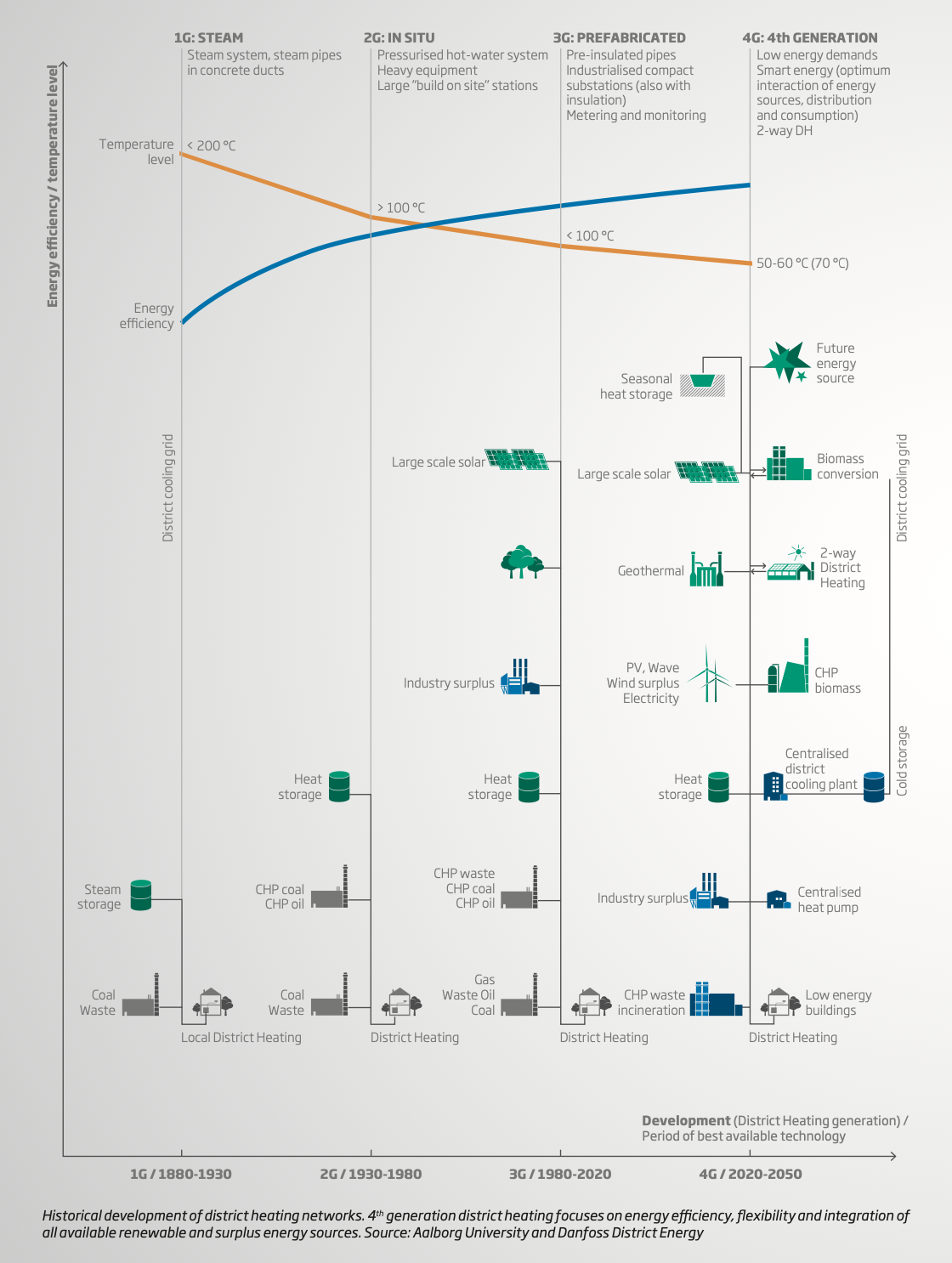

What Ogata Village is aiming to introduce is “The 4th Generation District Heating (4DH)”. In Japan, district heating is treated as a minor part of the energy policy, and the very existence of the concept of “generation” within it is almost unknown. 4DH is an idea proposed by a group at Aalborg University starting around 2014, in which a low supply temperature (50-60℃) is used to increase the efficiency of the entire system, while at the same time integrating renewable energy and waste heat 5 Aalborg University’s Professor Henrik Lund and the Sustainable Energy Planning Group lead the field and they have organized the annual International Conference on Smart Energy Systems. A historical paper by Lund gives overall concept of the 4DH: Lund, H. et. al, “4th Generation District Heating (4GDH): integrating smart thermal grids into future sustainable energy systems,” Energy, Volume 68, 15 April 2014, Pages 1-11. (Figure 1 and Table 1). Globally, the 3rd generation with supply temperatures of 80-90℃ is the mainstream, while Japan is dominated by the 1st and 2nd generation.

Figure 1: The 4th Generation District Heating

Table 1: Features of 4th Generation District Heating

1. Higher efficiency by lowering supply temperature

- High efficiency of the entire system

- Large temperature difference (25 degree Celsius or more) between the outgoing and return hot water

- Further efficiency improvement by latent heat recovery

2. Diversification of heat sources

- Expansion of resources to be utilized at low temperatures

- Utilization of factory waste heat and waste incineration heat

- Large-scale solar heat utilization and inter-seasonal heat storage

3. “Smart” heat and electricity

- Linkage of heat and electricity markets

- Storage using hot water tanks

- Conversion of electricity to heat by heat pumps, etc. (conversion of wind power to heat)

Denmark has first introduced district heating in 1900, but it was not until the oil crisis of 1973 that it was fully implemented. In 1976, the Electricity Supply Act made combined heat and power mandatory for new power plants, and in 1980, the Heat Supply Act was enacted to integrate electricity with district heating, thereby increasing the overall efficiency of the energy system as a whole for society 6 Ramboll “Agreement on Energy Efficiency Directive adopting 35 years of Danish Experience within DH and CHP” State of Green 2012. . Since the 1980s, when the issue of climate change emerged, the use of various types of biomass, such as wheat straw, wood chips, and domestic waste, as resources for district heating has expanded. Additionally, in recent years, the use of large solar heat systems and inter-seasonal heat storage using huge thermal storage tanks has also expanded 7 State of Green (2020) “District Energy“. .

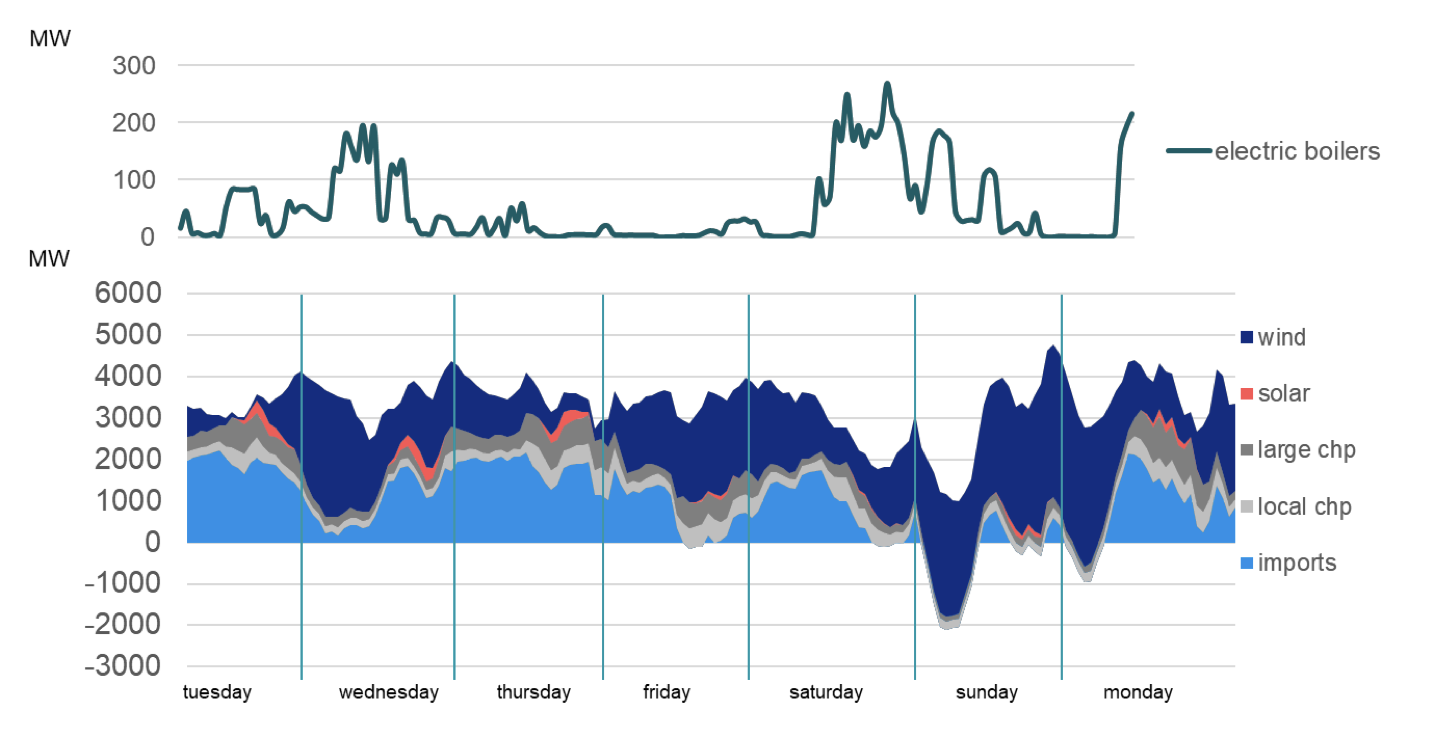

District heating, which covers approximately 70% of all houses and buildings in Denmark, is one of the two pillars of the country’s goal of 100% renewable energy by 2050. In Denmark, where variable wind power generation already accounts for more than 50% of the total electricity generation, district heating plays an important role in increasing flexibility. First, combined heat and power (CHP), the heat source of the district heating, operates via the electricity market to offset wind power fluctuations, and second, when wind power is in excess, the electricity market is at a low or negative price, and the power is converted to thermal heat for the district heating. In other words, the fluctuations in the electricity market are indirectly “stored” by the district heating’s hot water tanks (Figure 2).

Figure 2: Integration of wind and district heat supply in Denmark | Source: Danish Energy Agency

In conjunction with the advocacy of 4DH, district heating, which contributes to both decarbonization and the above-mentioned smart development, has been under review in recent years, and a series of “Heat Roadmap Europe” scenario studies at European University, led by Aalborg University since 2012, have shown a pathway to decarbonize thermal energy by 2050 8 European Commission “Heat Roadmap Europe – Low-carbon Heating and Cooling Roadmaps 2050 – A Final Report” 2018 . This is because, while the possibility of 100% renewable energy from wind and solar power has become a reality for electricity, decarbonization of the thermal sector, which accounts for a significant share of energy consumption, has not yet made much progress. 9 Worldwide, building heating and hot water energy accounts for 1/4 of total energy consumption, 11% of which is electrified, renewable sourced, or heat pumped. . The Heat Roadmap Europe also emphasizes the importance of district heating. The United Nations, under the leadership of UNEP, is also promoting district heating from the perspectives of climate protection, air pollution prevention, and the alleviation of energy poverty 10 UNEP District Energy in Cities Initiative. .

Japan’s lack of thermal policy and district heating

Japan, on the other hand, has no “thermal policy” to begin with. Individual elements such as air conditioning, heat pumps, insulation, and energy conservation can be found throughout the country, but a systematic “thermal policy” is lacking. In Japan, thermal energy consumption accounts for 80% of residential energy consumption in Sapporo, and 50% on average in Japan 11 In 2022, average residential energy consumption for Japan as a whole is 27.8% for hot water heating, 25.1% for heating, and 53% in total. Agency for Natural Resources and Energy, “Energy White Paper 2022”. . This policy absence can be attributed to historical and structural reasons in Japan’s energy policy.

First, Japan’s energy policy has historically had a strong political culture that emphasizes industry. The legal system is centered on “business laws” (such as the Electricity Business Act, Gas Business Act, and former Petroleum Business Act), and government offices are organized into divisions with jurisdiction over each business law, so it is safe to say that “energy industry policy” is based on a supply-side perspective. Therefore, among the demand-side of electricity, thermal energy, transportation, and industry, the framework of thermal energy is not included in the supply-side perspective of the business law system.

Second, the physics rationale of “exergy” is not taken into account. The importance of thermal policy lies in the fact that heat accounts for a large share of consumption as well as a small exergy (low grade). Exergy loss is high when the low exergy job of heating water with low temperature heat of several tens of degrees Celsius is directly supplied by high exergy energy such as kerosene, gas, or electricity.

The historical overlap of these factors, coupled with poor home insulation, has resulted in a heating environment in Japan that lacks a systematic “thermal policy” and is still in “chaos”. The low-efficiency, air-polluting wood stoves of the prewar period have been replaced by the more convenient kerosene stoves, and because of product development competition across the energy sources over time, a total of six types of heating equipment (kerosene + gas + electricity x stove + fan heater) are flooding homes throughout Japan without any uniformity. This has brought about “heating environment chaos” in which air conditioners have become a standard item in homes. This is the “minus one-meter problem” that stands in the way of Japan’s district heating.

In Japan, where there is no thermal policy, district heating is even more minor. It was first introduced in Senri New Town in 1970, timed to coincide with the 1970 Osaka World Exposition, and its purpose was to “prevent air pollution”. Since then, it has spread throughout Japan, and now 81 businesses nationwide supply heat to 142 districts (in 2021), accounting for less than 1% of Japan’s total energy consumption 12 Ministry of Economy, Trade and Industry, Heat Supply Business related website. . Moreover, it is a “vertical district heating” with a high energy density that covers air conditioning for multiple high-rise buildings, and does not expand over a large area as in Europe. In addition, most district heating is first-generation steam and second-generation high-temperature, high-pressure water. Neither the technology system or the existing infrastructure has been updated to date.

Chain of issues

When tackling the reality of the Ogata Decarbonization Leading Areas, we are faced with a cascade of challenges. The following is a list of the main challenges.

“The minus one-meter problem”

As mentioned above, even if district heating brings hot water to the entrance of a house, there are few houses in Japan, with the exception of parts of Hokkaido, where that hot water brought to the entrance can be used inside as hot water or heating. Following the example of the “last mile” in telecommunications and delivery, this can be called the “minus one meter problem”.

This is a serious barrier to district heating in Japan. Infrastructure for heating and hot water supply using hot water in houses is not widespread, and its product lines (hot water heat exchangers, thermal panel heaters, etc.) are almost non-existent. The major national house builder contracted to build new village housing in Ogata Village has no past experience in designing such housing. Although the residents are familiar with kerosene heaters and electrified systems, they likely have no experience with heating and hot water systems using hot water, apart from hot-water floor heating.

It is difficult from both a cost and practical standpoint for a local energy company to cover the development of the heating and hot water infrastructure inside a house, but without that replacement, the system will not be widely used. There is also a high hurdle for residents to be convinced to install a hot water system they have never used before, and all of these factors directly lead to increased costs.

Outgoing and return temperature difference problem

The key point of the 4th generation district heating is to lower the temperature of the supply to 50-60 degrees Celsius, while at the same time aiming to lower the return temperature to a difference of 25 degrees Celsius or higher. The objective is to supply the maximum amount of heat with a fixed amount of supplied hot water. This minimizes the amount of hot water to be supplied, minimizes the heat conduit, and minimizes the pump power, thereby minimizing both initial and operational costs. Even at the 3rd generation supply temperature of 80-90 degrees Celsius, the difference from the return temperature is designed to be at least 25 degrees Celsius.

In Japan, however, most hot water facilities are designed with a return temperature difference of about 5 degrees Celsius 13 In Japan, the outgoing and returning temperatures of cold and hot water are based on the assumption of chillers in air conditioning equipment, so it is generally considered that the outgoing and returning temperature difference of 5 degrees Celsius is set: 7 degrees Celsius to 12 degrees Celsius for cold water, and 45 degrees Celsius to 40 degrees Celsius for hot water. . Therefore, even if a 4th generation district heating system is designed on the supply side, it will be dragged down by the outgoing and returning temperature difference of existing facilities, limiting the improvement of the overall energy efficiency of the system.

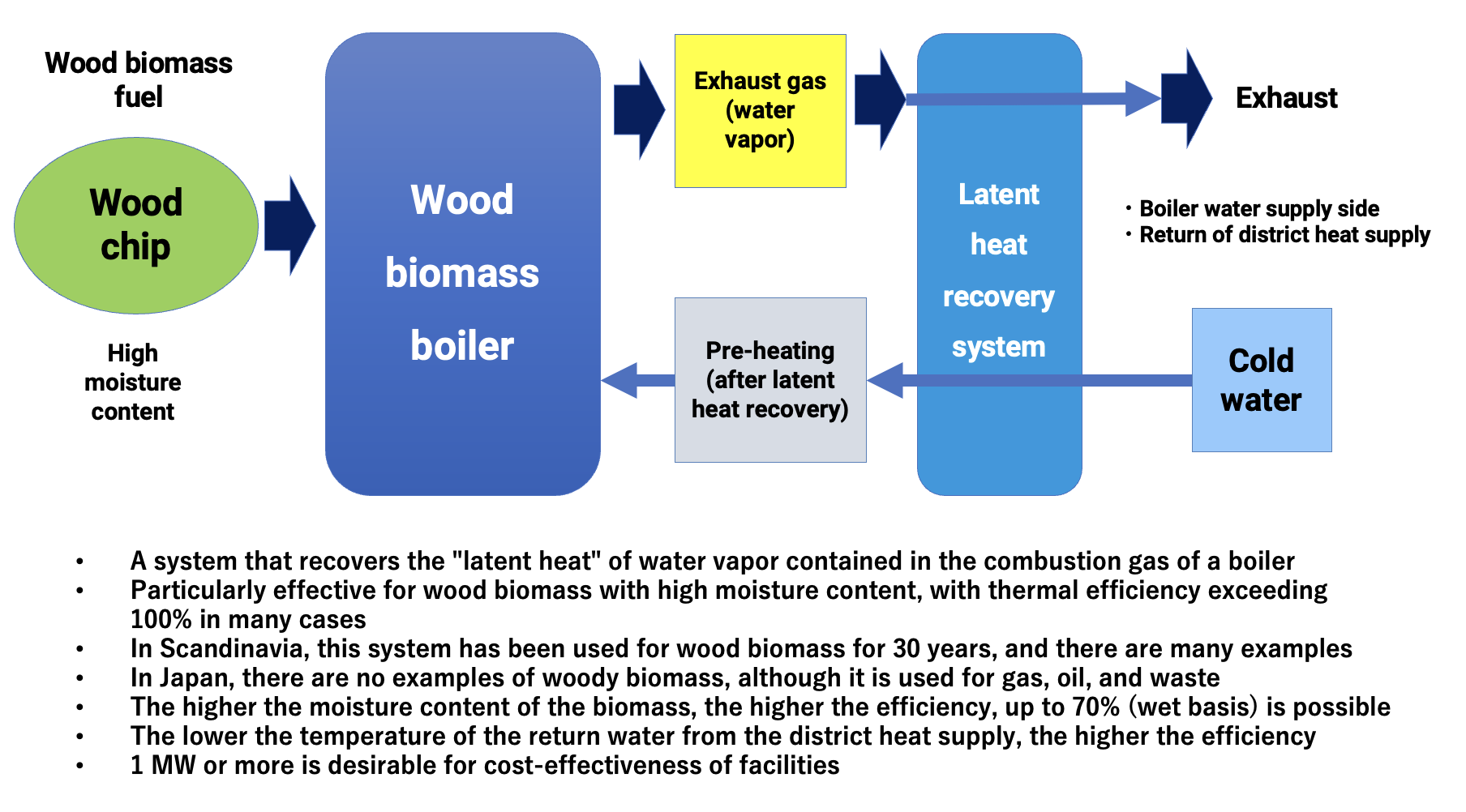

Technical capacity gap in boiler technology

Although it has been a common perception in the biomass industry for some time, once again, there are significant differences in biomass boiler technology between Japan and overseas. The difference between Japan and Scandinavia is significant, as shown in Figure 3, which shows a technology for reducing clinker (adhered ash in the boiler) and efficiently burning various biomass fuels with high water content (Figure 4), as well as a technology for latent heat recovery 14 This technology increases the overall efficiency of biomass boilers by 10-20% by recovering the residual heat of biomass fuel and the latent heat of steam generated during combustion with water before heating the boiler. In Scandinavia, where biomass combustion technology has been in the forefront, this technology began to spread in the early 1990s when environmental taxes were introduced, and today it has become a standard technology. In the 4th generation district heating, the return hot water temperature is as low as 25 degrees Celsius, so the efficiency of latent heat recovery is even higher (see Table 1). (Figure 5, which is not required in Ogata Village because of dried rice husks), which has not been used in Japan yet. We can see the large gap of technical capacity between Japan and Scandinavia, where technologies have been developed from these basic principles.

Barriers in construction and operating cost

In this case, it seems that the generous subsidies in the grant project by the Decarbonization Leading Areas will manage to break even, but district heating in Denmark and other Nordic countries is basically established without subsidies. In contrast to Japan, there are three major factors.

- Hard cost: the difference between domestic and foreign prices associated with imports (import costs, yen depreciation factor)

- Soft cost: difference between transaction costs and regulatory costs

- Difference in environmental taxes

Although 1 is unavoidable at this point, we expect the same level of domestic production of boilers in the future. 2 is mainly an issue for the private sector due to the large transaction costs caused by multiple intermediaries in construction and commercial transactions with multiple subcontractors, while the large regulatory costs associated with the time and effort involved in regulations are an issue for the politics and the administration. The huge procedures involved in obtaining subsidies are also included in the regulatory costs. Soft costs are a larger component of the price difference between domestic and foreign prices than hard costs, and they differ on the order of “X-fold” rather than “X-percentage”. 3 is a policy and institutional issue, and at present there is no prospect of its realization.

Off-site PPA

Although off the theme of this report, “off-site PPA,” which combines solar power generation and storage batteries, is also in a bottleneck between institutional design and market reality. The Ministry of the Environment envisions a physical PPA among the types of off-site PPAs, but due to the wholesale power exchange’s soaring price problem, no electricity suppliers have been found that can cooperate. The only possibility is cooperation by the former General Electric Utility, which is left to its discretion.

Even if virtual PPAs were allowed, there are no actual examples yet in Japan, and virtual PPAs in Decarbonized Leading Areas where FIT and FIP are not allowed also face significant challenges in realization.

None of these challenges are easy, but the aim is to solve them one by one while making improvements, and to spread the experience and lessons learned to Japan to make them take root.

—

Keywords: Ogata Village, Decarbonization Leading Area, 4th Generation District Heating, Denmark, thermal policy, biomass, latent heat recovery, rice husks, crystalline silica, minus one-meter problem

- 1Ogata Village, “Selection as the First Decarbonization Leading Area,” April 28, 2022. (in Japanese)

- 2Council for National and Local Decarbonization, Cabinet Secretariat (in Japanese)

- 3Ogata Village has been working to materialize district heating through the Ministry of Internal Affairs and Communications’ “Distributed Energy Infrastructure Project Master Plan Development” in 2015 and the Ministry of Environment’s “Decarbonized Community Development Model Formation Project” in 2019.

- 4Crystalline silica (cristobalite) is almost non-existent in nature except for minerals, but amorphous silica crystallizes when rice husks and rice straw are heated to high temperatures. The International Agency for Research on Cancer (IARC) states that people suffering from silicosis are at risk of developing lung cancer and recommends that crystalline silica dust be controlled to < 0.1 mg/m3 for occupational health reasons. In Japan, the Occupational Safety and Health Law and its enforcement ordinance stipulate “labeling requirements”.

- 5Aalborg University’s Professor Henrik Lund and the Sustainable Energy Planning Group lead the field and they have organized the annual International Conference on Smart Energy Systems. A historical paper by Lund gives overall concept of the 4DH: Lund, H. et. al, “4th Generation District Heating (4GDH): integrating smart thermal grids into future sustainable energy systems,” Energy, Volume 68, 15 April 2014, Pages 1-11.

- 6Ramboll “Agreement on Energy Efficiency Directive adopting 35 years of Danish Experience within DH and CHP” State of Green 2012.

- 7State of Green (2020) “District Energy“.

- 8European Commission “Heat Roadmap Europe – Low-carbon Heating and Cooling Roadmaps 2050 – A Final Report” 2018

- 9Worldwide, building heating and hot water energy accounts for 1/4 of total energy consumption, 11% of which is electrified, renewable sourced, or heat pumped.

- 10

- 11In 2022, average residential energy consumption for Japan as a whole is 27.8% for hot water heating, 25.1% for heating, and 53% in total. Agency for Natural Resources and Energy, “Energy White Paper 2022”.

- 12Ministry of Economy, Trade and Industry, Heat Supply Business related website.

- 13In Japan, the outgoing and returning temperatures of cold and hot water are based on the assumption of chillers in air conditioning equipment, so it is generally considered that the outgoing and returning temperature difference of 5 degrees Celsius is set: 7 degrees Celsius to 12 degrees Celsius for cold water, and 45 degrees Celsius to 40 degrees Celsius for hot water.

- 14This technology increases the overall efficiency of biomass boilers by 10-20% by recovering the residual heat of biomass fuel and the latent heat of steam generated during combustion with water before heating the boiler. In Scandinavia, where biomass combustion technology has been in the forefront, this technology began to spread in the early 1990s when environmental taxes were introduced, and today it has become a standard technology. In the 4th generation district heating, the return hot water temperature is as low as 25 degrees Celsius, so the efficiency of latent heat recovery is even higher (see Table 1).